How Closed-Loop Stepper Motors Can Improve Your Machinery's Precision?

Precision is a vital aspect of many machinery applications, and achieving high levels of accuracy is crucial for optimal performance. Closed-loop stepper motors have emerged as a solution to enhance precision in various industries. In this article, we will delve into the world of closed-loop stepper motors, exploring their functionality, advantages over traditional open-loop systems, and how they can significantly improve the precision of your machinery.

Understanding Closed-Loop Stepper Motors

Closed-loop stepper motors combine the advantages of traditional stepper motors with feedback systems to enhance precision. Unlike open-loop systems that operate without position feedback, closed-loop stepper motors utilize encoder or sensor feedback to continuously monitor and adjust the motor's position, ensuring accurate positioning and eliminating the issues associated with missed steps.

The Working Principle of Closed-Loop Stepper Motors

Closed-loop stepper motors incorporate position feedback devices, typically encoders, to provide real-time information about the motor's actual position. This feedback is compared to the desired position generated by the control system. Based on the comparison, the control system adjusts the motor's operation, compensating for any deviations and ensuring precise positioning.

Advantages of Closed-Loop Stepper Motors

-

Improved Positioning Accuracy

The primary advantage of closed-loop stepper motors is their ability to deliver superior positioning accuracy. By continuously monitoring the motor's position and making real-time adjustments, these motors eliminate the cumulative errors that can occur in open-loop systems, resulting in significantly improved precision.

-

Increased Torque and Performance

Closed-loop stepper motors can deliver higher torque compared to open-loop systems. The feedback mechanism allows for better utilization of the motor's capabilities, enabling more demanding applications and improved overall performance.

-

Enhanced Fault Detection and Recovery

Closed-loop stepper motors provide built-in fault detection capabilities. By monitoring the position and movement of the motor, these motors can detect errors such as missed steps or stalls. The control system can then take corrective actions, minimizing the impact of faults and improving the reliability of the machinery.

-

Higher Speed and Acceleration

Closed-loop stepper motors can achieve higher speeds and accelerations compared to open-loop systems. The feedback mechanism enables precise control, allowing for faster and smoother movements without sacrificing accuracy.

Implementing Closed-Loop Stepper Motors in Machinery

-

Integration with Motion Controllers

To effectively utilize closed-loop stepper motors, they must be integrated with compatible motion controllers that support closed-loop operation. The motion controller receives feedback from the motor's position sensor and adjusts the motor's operation accordingly.

-

Wiring and Connectivity Considerations

Proper wiring and connectivity are vital for the successful implementation of closed-loop stepper motors. Ensure that the motor, encoder, motion controller, and power supply are connected correctly, following the manufacturer's guidelines and specifications.

-

Calibration and Tuning

Calibration and tuning are essential steps in optimizing the performance of closed-loop stepper motors. This process involves setting up the motion controller, configuring the control parameters, and fine-tuning the motor's operation for optimal precision and performance.

Industries and Applications Benefitting from Closed-Loop Stepper Motors

-

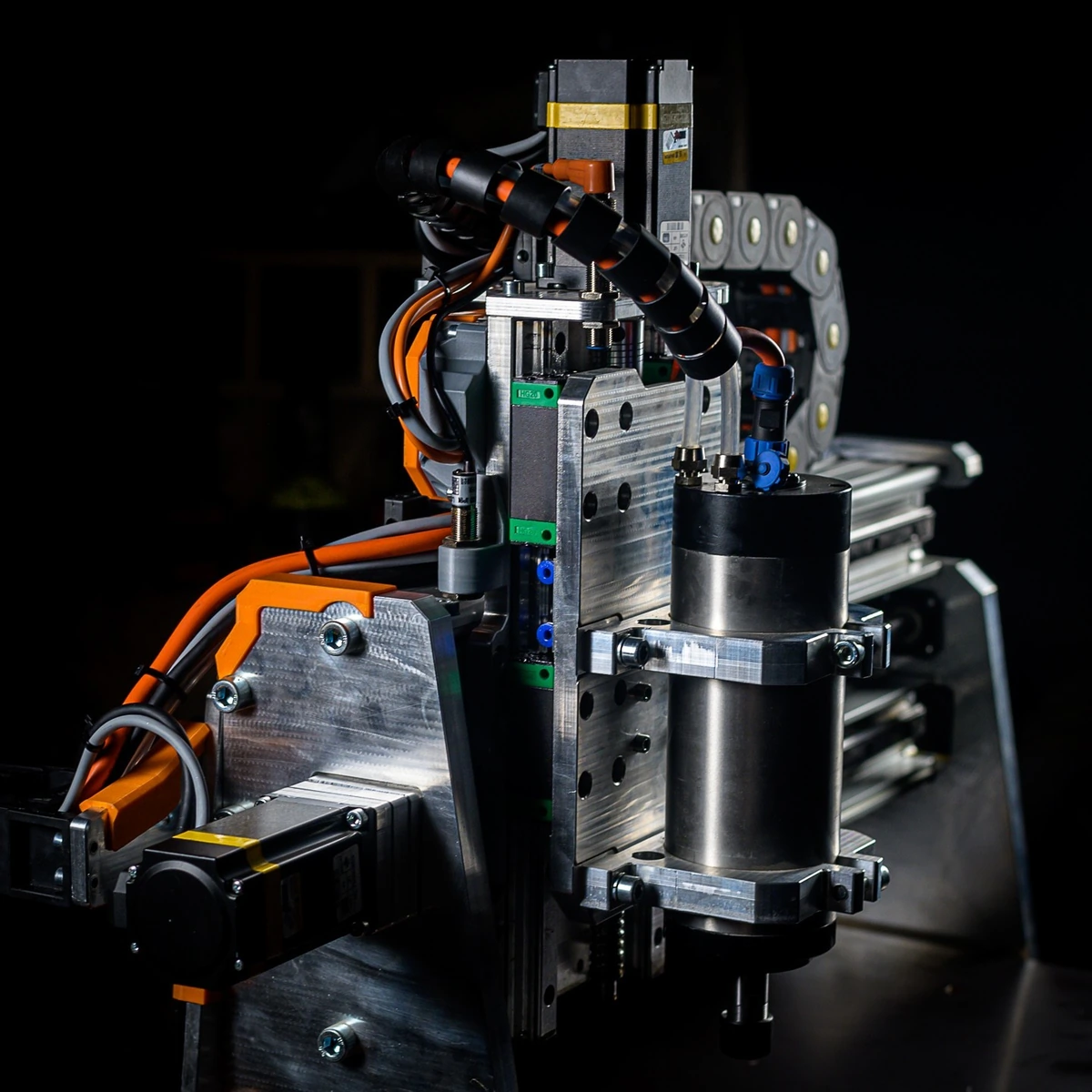

CNC Machining

Closed-loop stepper motors find extensive use in CNC machining applications, where precision and accuracy are critical. They enable precise control of cutting tools, resulting in superior surface finish and dimensional accuracy.

-

3D Printing

The precise movement and positioning required in 3D printing make closed-loop stepper motors an ideal choice. They ensure accurate layering, dimensional stability, and consistent print quality.

-

Robotics and Automation

Closed-loop stepper motors are widely employed in robotics and automation systems, providing precise movement control for robotic arms, pick-and-place machines, and other automated processes.

-

Medical Devices and Instruments

Medical devices and instruments often require high precision and accuracy. Closed-loop stepper motors are utilized in applications such as surgical robots, diagnostic equipment, and laboratory automation, ensuring reliable and precise operation.

Conclusion

Closed-loop stepper motors offer a significant advancement in precision for various machinery applications. Their ability to continuously monitor and adjust the motor's position, coupled with the benefits of traditional stepper motors, leads to improved accuracy, increased torque, fault detection, and higher speed capabilities. By integrating closed-loop stepper motors into machinery systems, industries such as CNC machining, 3D printing, robotics, and medical devices can achieve enhanced precision and performance.

Leave a Reply