How do I solve stepper motor vibration?

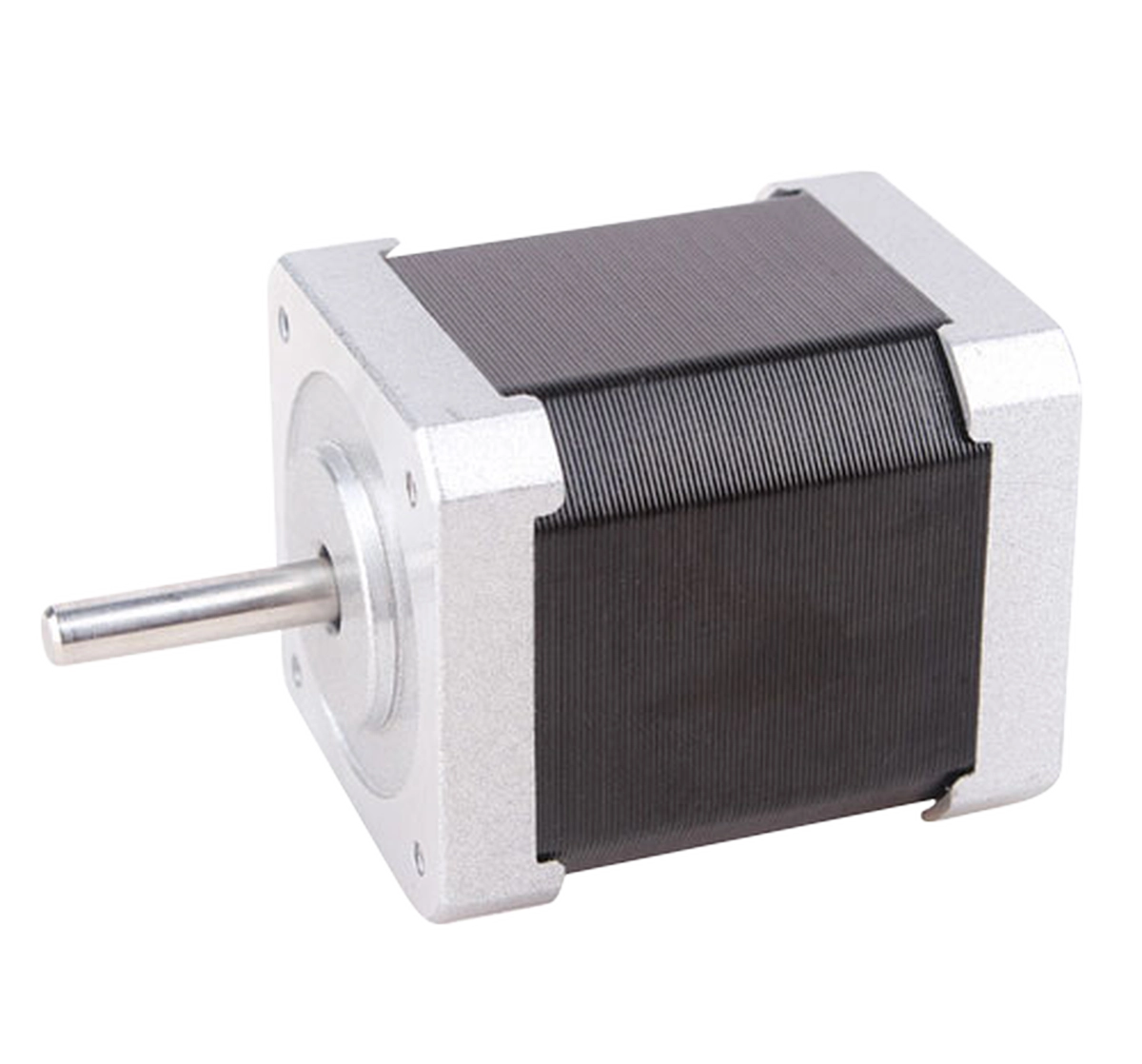

Stepper motors are commonly used in precision positioning applications because of their ability to convert electrical pulses into accurate rotary or linear motion. However, issues such as resonance and torque pulsations can cause vibration, which can reduce positioning accuracy. There are several ways to control stepper motor vibration.

Reduced excitation frequency

Stepping in a stepper motor creates torque pulsations that cause vibration at the motor's stepping frequency. Reducing the excitation frequency of the drive will reduce the frequency of the torque pulsations and the overall vibration amplitude. However, an excitation frequency that is too low will negatively affect torque and control.

Using micro-stepping

Micro-stepping increases resolution by dividing steps into smaller increments. The greater the number of micro-steps, the smoother the torque output, thus reducing resonance. Proper microstepping adjustments can filter out vibration frequencies while maintaining adequate torque and positional accuracy. However, too many microsteps can lead to motor instability.

Adding a damper

Adding a mechanical damper, such as a rubber vibration isolator, passively absorbs resonance. The damper needs to target a specific resonant frequency while maintaining motor stiffness for good positioning control. External dampers add cost and complexity but are simple to implement.

Conclusion

Stepper motor vibration originates from changes in torque that cause mechanical resonance. Vibration can be effectively controlled by using a variety of methods. This enables optimal stepper motor performance, smooth motion, and precise positioning accuracy.

Leave a Reply