What are the typical torque ratings for NEMA 8 motors?

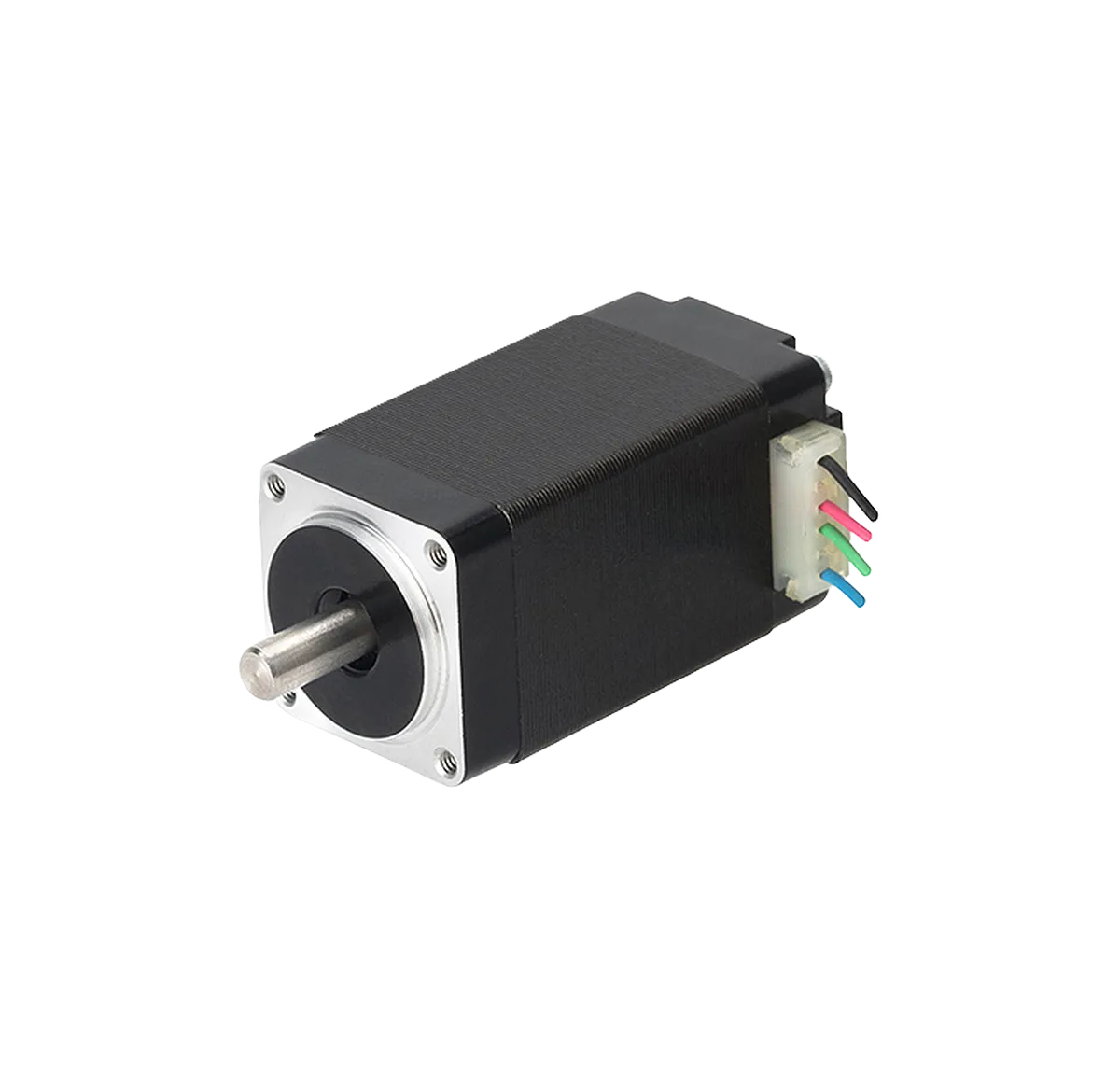

NEMA 8 motors are a common type of low power motor used in a variety of industrial and commercial applications. Understanding the torque capabilities of these motors is important for proper motor selection and application. This article will provide an overview of NEMA8 motor torque ratings and discuss the factors that affect torque output.

Typical Torque Output

The torque produced by a NEMA8 motor depends on the size, construction, efficiency level and operating speed of the motor. Typical stall torque ranges from 0.59Nm to 11Nm for NEMA8 motors on 120V power supplies. Lower horsepower motors in NEMA8 frames produce stall torque values at the lower end of this range. Larger motors produce higher stall torque.

The motor will always run at a lower running torque than the blocking torque. For general purpose NEMA8 motors, the range of running torque values is approximately 0.3Nm to 5.5Nm. Reducers are often used with NEMA8 motors to increase torque.

Factors affecting torque

The torque output of a 20 Series motor is affected by the following factors:

- Rated Horsepower: Higher horsepower motors produce more torque.

- Number of Poles: Motors with more poles tend to have higher torque.

- Power: Torque varies according to input voltage.

- Efficiency Levels: A more efficient motor produces more torque.

- Torque-Speed Curve: Torque decreases at higher speeds.

- Gear Unit: Gearboxes increase output torque.

Proper motor sizing, construction, and gear selection allow NEMA 8 motors to be customized to the specific torque requirements of the application.

Conclusion

NEMA 8 motors have an important place in industrial motion control. Their relatively low torque capacity makes them ideal for light-duty applications requiring low horsepower, low-speed operation and low inertia.

Leave a Reply