What is the difference between a stepper and a hybrid stepper?

In the realm of electric motors, precision in control is paramount. Stepper motors are widely utilized for their ability to ensure precise positioning and speed control. Among these, the standard stepper and the hybrid stepper motor are prominent. To fully understand their difference, one must delve into their construction, operation, and distinct features.

Understanding Stepper Motors

Definition and Principle of Operation

Stepper motors are digitally-driven, synchronous electric motors that convert electrical pulses into mechanical rotation. Each pulse moves the rotor in fixed angle increments, known as steps. This feature allows for exact positioning without the need for feedback systems.

Types of Stepper Motors

- Permanent Magnet Stepper Motors

- Variable Reluctance Stepper Motors

- Hybrid Stepper Motors

Permanent Magnet Stepper Motors

Construction

Permanent magnet (PM) stepper motors create motion using a permanent magnet as the rotor. The stator is designed with pole pairs that can be magnetically energized to attract or repel the magnetized rotor, causing it to step.

Characteristics

These steppers provide good torque at low speeds, are simple in design, and have a reasonable amount of detent torque, which provides the motor with the ability to hold a position when it is not energized.

Variable Reluctance Stepper Motors

Construction

Variable reluctance (VR) stepper motors do not use a magnet. Instead, they consist of a plain iron rotor and a stator wound with electromagnetic coils. The rotor steps as it aligns with the magnetic field generated by the electrified stator coils.

Characteristics

VR stepper motors are known for achieving higher step rates and are typically lighter due to the lack of permanent magnets. However, they generally have less torque, especially at low speeds.

Hybrid Stepper Motors

Construction

Hybrid stepper motors combine aspects of both PM and VR motors. They utilize a rotor with permanent magnets as well as teeth to enhance magnetic flux linking with the stator.

Characteristics

Hybrid steppers are characterized by their high torque and low detent torque, improved step resolution, and their ability to maintain high torque throughout a broad range of stepping speeds. They are more complex in design, which can increase manufacturing costs.

The Distinct Differences

- Torque: Hybrid steppers typically offer higher torque over the same physical motor size compared to PM and VR steppers.

- Resolution: The presence of teeth on both rotor and stator in hybrid steppers allows for a greater number of steps for each revolution, offering higher resolutions.

- Performance: A hybrid stepper motor provides better performance in terms of smoothness of operation and ability to start, stop, and reverse direction.

- Speed: PM steppers have limitations when it comes to speed due to the potential for rotor slipping. Hybrid steppers, on the other hand, can often operate at higher speeds as they have better holding and dynamic torque.

- Efficiency: Hybrid steppers are generally more efficient due to the better match of magnetic materials in their construction, reducing energy losses.

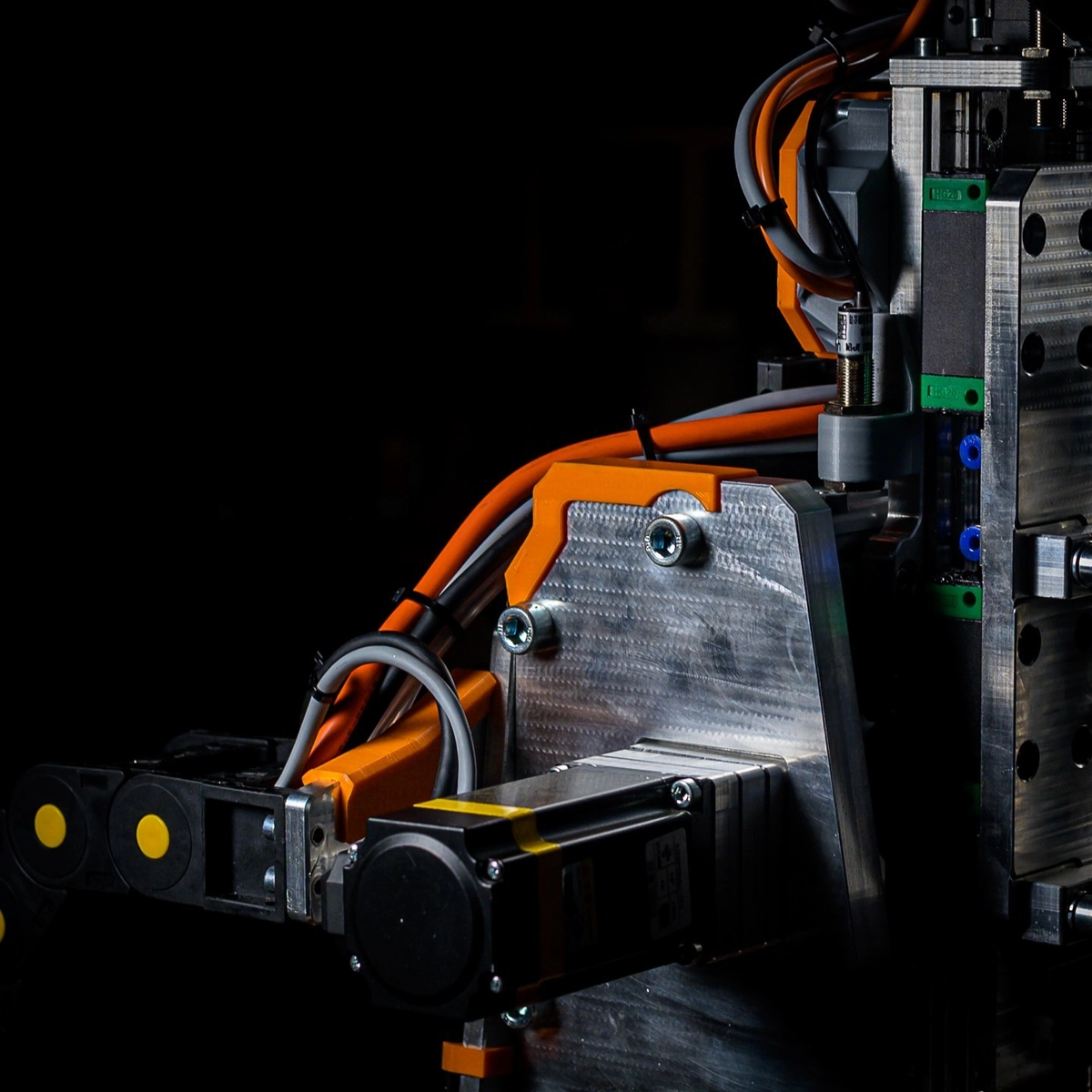

- Applications: While PM and VR steppers are suitable for low to moderate demand applications due to their simpler and more cost-effective design, hybrid steppers are often preferred in applications that require a high degree of accuracy, such as in CNC machines, 3D printers, and robotics.

Conclusion

In summary, the primary difference between a standard stepper motor and a hybrid stepper is found in the blend of technology that takes advantage of the strengths of both permanent magnet and variable reluctance designs. Opting for a hybrid stepper motor essentially means choosing a motor with higher precision, efficiency, and performance capabilities, albeit often at a higher cost. The choice between these motor types will largely depend on the specific requirements of the application,balance of cost versus performance, and precise control needs.

Leave a Reply