What's inside in a stepper motor?

Stepper motors are widely used in various applications that require precise and controlled rotational motion. These motors operate on a unique principle that allows them to move in discrete steps, making them ideal for applications such as robotics, 3D printers, CNC machines, and automation systems. To understand the inner workings of a stepper motor, it is essential to delve into its construction and components. In this article, we will delve into the internal components and working principles of a stepper motor.

I. Overview of Stepper Motors

Before delving into the inner workings of a stepper motor, let's first establish a basic understanding of their purpose and functionality. Stepper motors are electromechanical devices that transform electrical pulses into discrete steps or increments of motion. Unlike traditional motors that rotate continuously, stepper motors move in precise, predetermined increments and can maintain a specific position without the need for a position feedback sensor.

II. Internal Components of a Stepper Motor

Rotor

The rotor is the moving part of the stepper motor. It consists of a shaft and a permanent magnet or teeth, depending on the motor type. The rotor's design and geometry determine the stepping resolution and torque characteristics of the motor.

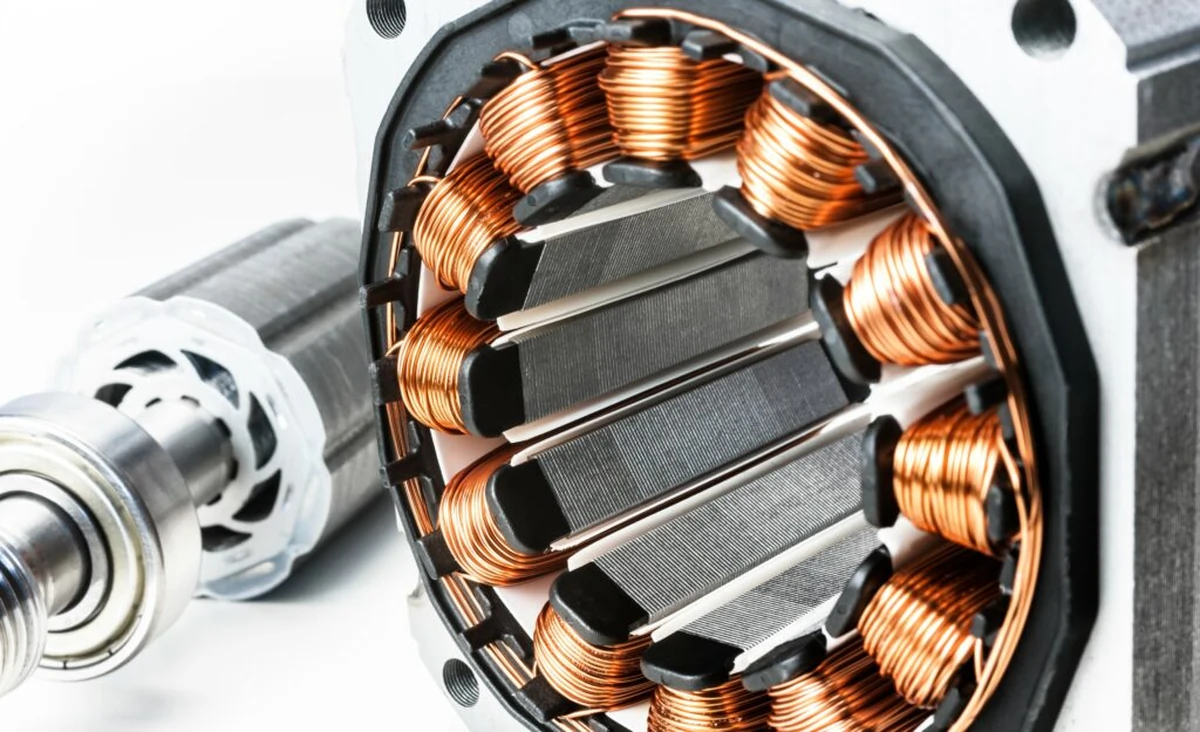

Stator

The stator is the stationary part of the stepper motor. It includes a core made of laminated iron or steel, which provides a low-reluctance path for the magnetic flux. The stator also houses the stator windings, which are energized to create the magnetic fields that interact with the rotor.

Windings

The windings are coils of wire wound around specific sections of the stator. The number of windings and their arrangement determine the motor's step angle and performance characteristics. The windings are typically made of copper wire to ensure efficient electrical conductivity. Stepper motors are classified into different types based on the number of phases they possess. Common stepper motor configurations include two-phase, three-phase, and four-phase motors. Each phase represents a set of windings in the stator, and the number of windings determines the motor's step angle and resolution. For example, a four-phase stepper motor will have four sets of windings, allowing for finer control and smaller step angles.

Pole Pieces

Pole pieces are sections of the stator that concentrate the magnetic flux generated by the energized windings. The pole pieces help create distinct poles and facilitate the interaction with the rotor's magnetic field.

Bearings

Stepper motors incorporate bearings to support the rotor shaft and reduce friction. High-quality bearings ensure smooth rotation and minimize mechanical losses in the motor.

III. Working Principles of a Stepper Motor

Electromagnetic Interaction

The operation of a stepper motor is based on the interaction between the magnetic fields generated by the stator windings and the rotor's magnetic field. By energizing the windings in a particular sequence, the magnetic fields attract or repel each other, causing the rotor to move in discrete steps.

Step Sequencing

Stepper motors use a variety of step sequencing methods, including:

- Full Step

Energizing a single winding at a time, resulting in a full step or the motor's maximum angular displacement per step.

- Half Step

Energizing two adjacent windings simultaneously, resulting in a half step or half of the motor's maximum angular displacement per step. Half stepping allows for finer resolution but may sacrifice torque.

- Microstepping

Applying currents at varying levels to the windings, resulting in smaller angular displacements per step. Microstepping allows for even finer resolution and smoother motion but requires more complex control circuitry.

IV. Control and Drive Circuitry

Motor Driver

A motor driver is an electronic circuit that controls the energization of the stator windings based on the desired motion. It receives control signals, typically in the form of digital pulses, and generates the appropriate current levels and sequences to drive the motor.

Pulse Generator

In many applications, a pulse generator or controller generates the control signals for the motor driver. The pulse generator generates pulses according to the desired motion profile, such as speed, acceleration, and positioning.

Feedback System (Optional)

Some stepper motors may incorporate a feedback system, such as an encoder or a position sensor, to provide accurate position feedback to the control circuitry. This allows for closed-loop control and improves the motor's accuracy and performance.

V. Conclusion

Stepper motors are complex electromechanical devices that provide precise control and positioning functions. The internal components of a stepper motor mainly include the stator, rotor, windings, pole pieces, and bearings. Stepper motors are widely used in robotics, 3D printing, CNC machines, and automation systems due to their ability to provide precise positioning and cost-effectiveness.

Leave a Reply