Closed Loop Stepper Motors for CNC machines

In the world of Computer Numerical Control (CNC) machines, precise and accurate motion control is essential for achieving high-quality results. Closed-loop stepper motors have emerged as a popular choice for CNC applications due to their ability to combine the benefits of stepper motors with closed-loop feedback systems. In this article, we will explore the concept of closed loop stepper motors, their advantages, working principles, and their significance in CNC machines.

I. Understanding Stepper Motors

Basic Functionality

Stepper motors are widely used in CNC machines for their ability to provide precise, incremental motion control. Unlike traditional motors that rotate continuously, stepper motors move in discrete steps, allowing for accurate positioning and control. They operate by converting electrical pulses into rotational motion through the interaction of magnetic fields within the motor.

Open Loop Stepper Motors

Open loop stepper motors are the most common type of stepper motor used in CNC machines. They rely on an open-loop control system, meaning they do not provide feedback on the motor's actual position. While open loop systems are cost-effective and simple to implement, they may be susceptible to missed steps and position errors due to factors like varying loads, resonance, or motor malfunctions.

II. Introduction to Closed Loop Stepper Motors

Closed Loop Feedback System

Closed loop stepper motors, also known as hybrid stepper motors, incorporate a closed-loop feedback system that provides real-time position information. This feedback is achieved through the integration of an encoder or a position sensor with the motor. The sensor continuously monitors the motor's actual position and compares it to the desired position, allowing for precise control and error correction.

Advantages of Closed Loop Stepper Motors

Closed loop stepper motors offer several advantages over open loop systems in CNC applications:

- Improved Accuracy and Precision

The closed-loop feedback system enables precise position control, reducing the chances of missed steps and position errors. This results in improved accuracy and higher-quality output in CNC machining.

- Enhanced Dynamic Response

Closed loop stepper motors provide faster response times and improved dynamic performance compared to open loop systems. They can adapt to varying loads, changes in acceleration, and deceleration more effectively, ensuring smoother and more reliable motion.

- Error Detection and Correction

The closed loop feedback system enables the detection and correction of errors in real-time. If the motor deviates from the desired position, the feedback system can adjust the motor's operation to correct the error, maintaining accurate positioning throughout the operation.

- Increased Torque at High Speeds

Closed loop stepper motors can deliver higher torque at high speeds compared to open loop systems. This is due to the ability to monitor and adjust the motor's operation based on the position feedback, optimizing torque output.

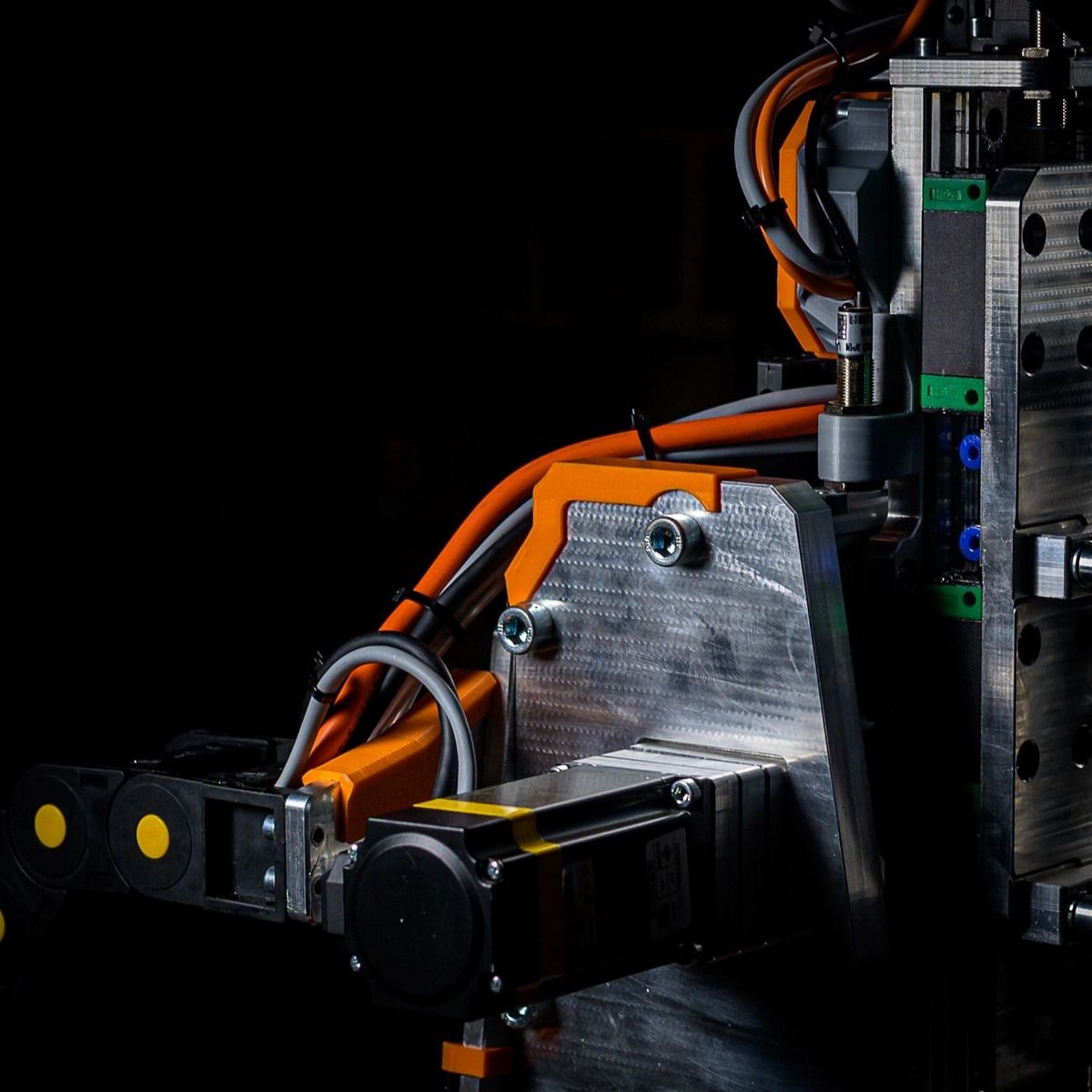

III. Closed loop system

In addition to the closed-loop stepper motor, the closed-loop system also includes the spindle, linear guide slider, controller, and precision sensor. The spindle generally uses an air-cooled spindle to meet the usage requirements, but if you have special requirements, you can also replace it according to your application.

IV. Working Principles of Closed Loop Stepper Motors

Encoder or Position Sensor

Closed loop stepper motors incorporate an encoder or a position sensor that provides continuous feedback on the motor's position. The sensor detects the rotor's position and sends signals to a controller or driver, allowing for real-time position monitoring.

Controller and Feedback Loop

The controller or driver receives the position feedback from the sensor and compares it to the desired position. If any deviation is detected, the controller adjusts the motor's operation to correct the error. This closed-loop feedback system ensures accurate and precise positioning of the motor.

V. Significance in CNC Machines

- Improved Machining Accuracy

Closed loop stepper motors significantly enhance the accuracy of CNC machines. By continuously monitoring the motor's position and correcting any errors, these motors enable precise control over tool paths and positioning, resulting in higher machining accuracy and finer details in the finished workpiece.

- Increased Reliability and Consistency

The closed-loop feedback system in stepper motors increases the reliability and consistency of CNC operations. It minimizes the chances of missed steps or position errors, ensuring consistent and repeatable results across multiple machining operations.

- Compatibility with Various Loads

Closed loop stepper motors can handle a wide range of loads, including varying loads encountered in CNC machining. The position feedback enables the motor to adapt to changes in load conditions, maintaining accurate positioning and preventing issues such as stalling or missed steps.

- Error Detection and Fault Prevention

The closed-loop feedback system in closed loop stepper motors allows for real-time error detection. If the motor encounters any issues, such as excessive load or mechanical faults, the feedback system can detect anomalies and trigger alarms or protective measures, preventing potential damage to the motor or the workpiece.

Conclusion

Closed-loop stepper motors combine the advantages of stepper motors with closed-loop feedback systems, offering more significant benefits compared to open-loop systems. They provide the ability for real-time position feedback to ensure precise and reliable motion control in CNC machines, leading to improved machining accuracy, consistency, and reliability, ultimately contributing to the production of high-quality and complex workpieces.

Leave a Reply