Reasons and Solutions for stepper motor out of step

In normal operation, the stepper motor moves one step angle, i.e. one step forward, for each control pulse received. If the control pulse is input continuously, the motor rotates continuously accordingly. Stepping motor out of step includes lost step and overstep. When the step is lost, the number of steps advanced by the rotor is less than the number of pulses; when the step is crossed, the number of steps advanced by the rotor is more than the number of pulses. The number of steps for one lost step and overstep is equal to an integer multiple of the number of running beats. A serious lost step will cause the rotor to stay in one position or vibrate around one position, and a serious overstep will cause the machine to overshoot.

Lost step causes and strategies

-

The acceleration of the rotor is slower than the rotating magnetic field of the stepper motor

Reason

When the acceleration of the rotor is slower than the rotating magnetic field of the stepping motor, i.e., when it is lower than the speed of phase change, the stepping motor will generate out-of-step. This is because the power input to the motor is insufficient, and the synchronizing torque generated in the stepper motor does not allow the rotor speed to follow the rotating speed of the stator magnetic field, thus causing the out-of-step. Since the dynamic output torque of a stepper motor decreases as the frequency of continuous operation increases, any operating frequency higher than that will produce a lost step. This lost step indicates that the stepper motor does not have enough torque and does not have enough dragging capacity.

Solution

Increase the electromagnetic torque generated by the stepping motor itself. For this purpose, the driving current can be increased appropriately within the rated current range; when the torque is insufficient in the high frequency range, the driving voltage of the driving circuit can be increased appropriately; change to a stepping motor with large torque, etc. b. Reduce the torque that needs to be overcome by the stepping motor. This can be done by appropriately reducing the motor operating frequency to increase the output torque of the motor; setting a longer acceleration time so that the rotor obtains sufficient energy.

-

Reason

The average speed of the rotor is higher than the average rotation speed of the stator magnetic field when the stator is energized and excited for a longer time than the time required for the rotor to step further, then the rotor obtains too much energy during the stepping process, which makes the output torque produced by the stepping motor increase, and thus causes the motor to overstep. When the stepping motor is used to drive the mechanism that makes the load move up and down, it is more likely to produce the phenomenon of overstepping, which is because the torque required by the motor decreases when the load moves downward.

Solution

Reduce the drive current of the stepping motor to reduce the output torque of the stepping motor.

-

Inertia of stepping motor and load

Reason

Due to the inertia of the stepping motor itself and the load it carries, the motor can’t start and stop immediately during operation, but loses steps during starting and oversteps during stopping.

Solution

Through a process of acceleration and deceleration, i.e. starting at a lower speed, then gradually accelerating to a certain speed, and then gradually decelerating until it stops. Reasonable and smooth acceleration and deceleration control is the key to ensuring reliable, efficient, and accurate operation of the stepper drive system. Public number "mechanical engineering literature", the engineer's gas station!

-

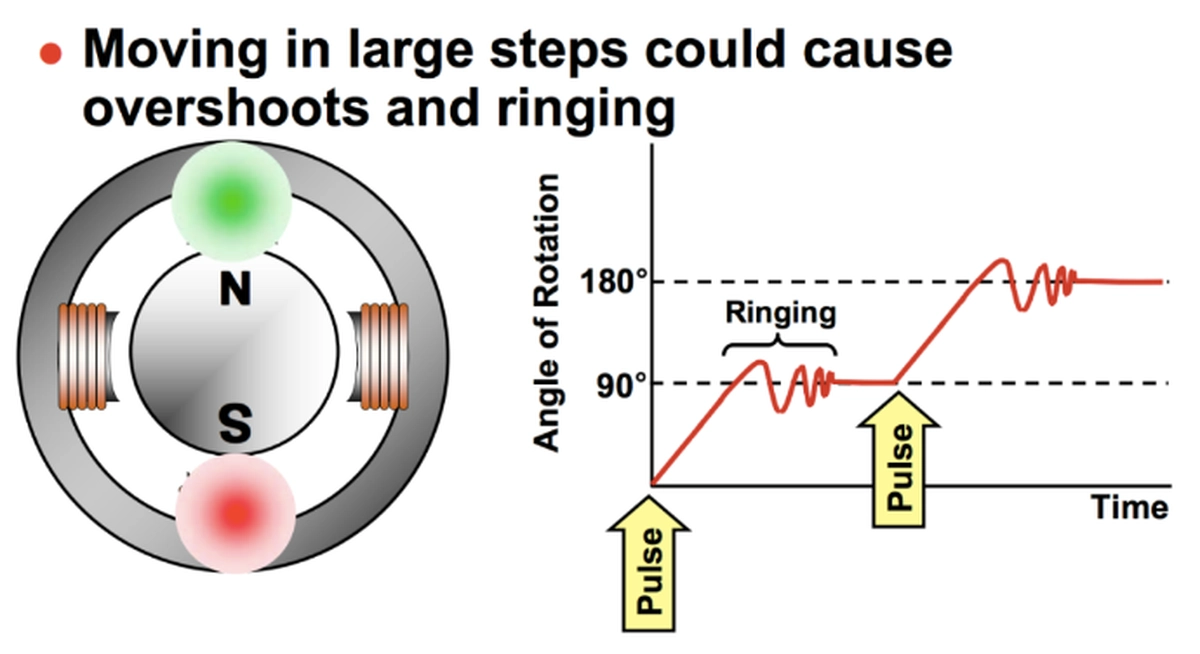

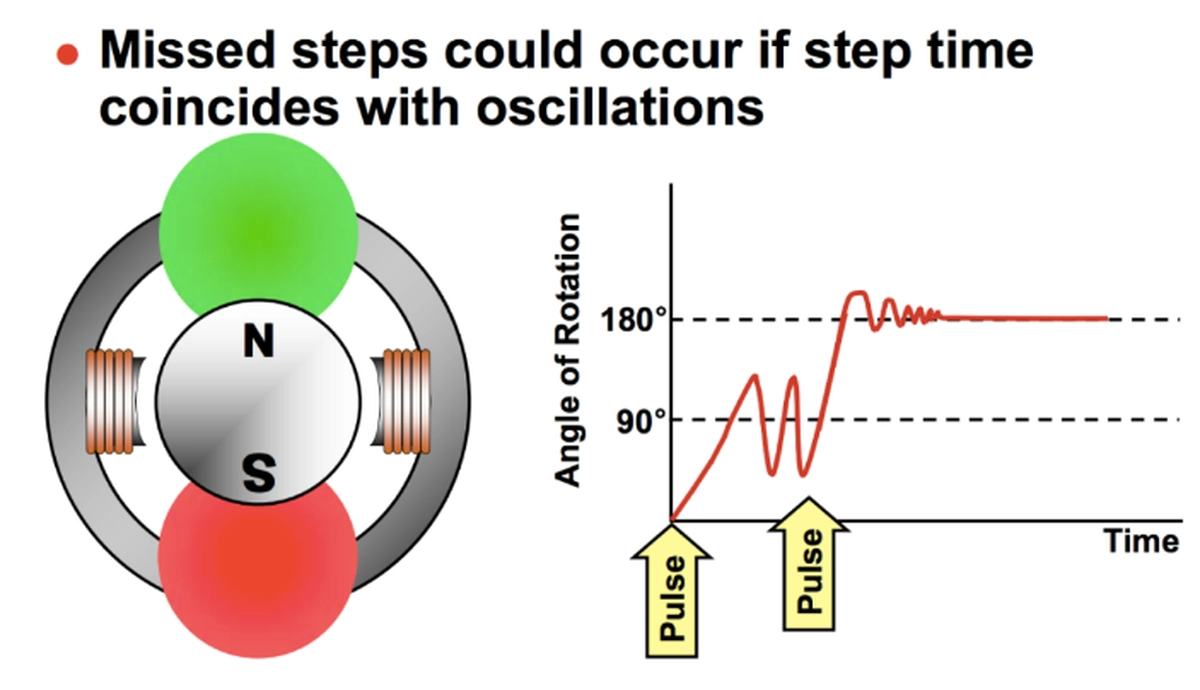

Resonance of stepping motor

Reason

Reason

Resonance is also a cause of out-of-step. When the stepper motor is in continuous operation, if the frequency of the control pulse is equal to the intrinsic frequency of the stepper motor, resonance will occur. Within one control pulse period, the vibration is not sufficiently attenuated and the next pulse comes, thus the dynamic error is greatest near the resonance frequency and causes the stepper motor to miss a step.

Solution

Appropriately reduce the drive current of the stepper motor; use subdivided drive method; use damping methods, including mechanical damping method. All of the above methods can effectively eliminate motor oscillation and avoid the phenomenon of out-of-step.

-

Loss of pulse when changing direction

Reason

The performance is accurate in any direction, but once the direction is changed, the deviation is accumulated, and the more times it is changed, the more it deviates.

Solution

The general stepping driver has certain requirements on the direction and pulse signals, such as the direction of the signal in the first pulse rising edge or falling edge (different driver requirements are not the same) before the arrival of a few microseconds to be determined, otherwise there will be a pulse of the angle of operation and the actual need to turn the opposite direction, the final failure phenomenon is manifested in the more deviation, the smaller the breakdown is more pronounced, the Solution is mainly used in the software to change the logic of sending pulse The Solution is mainly to use software to change the logic of sending pulses or add a delay.

-

Software defects

Reason

It is not uncommon for the control program to lead to out-of-step, and it is necessary to check whether there is any problem with the control program.

Solution

Can not find the cause of the problem for a while, some engineers will let the stepper motor run for some time to re-find the origin homing.

Leave a Reply