Spindle and servo motor, what is the difference?

In the world of industrial automation and machinery, spindle motors and servo motors are two critical components that play distinct roles in various applications. Understanding the differences between these two types of motors is essential for engineers and technicians to ensure optimal performance and efficiency in their systems. This article delves into the technical aspects, performance characteristics, and typical applications of spindle motors and servo motors, providing a comprehensive comparison.

Introduction to Spindle Motors and Servo Motors

Spindle Motors

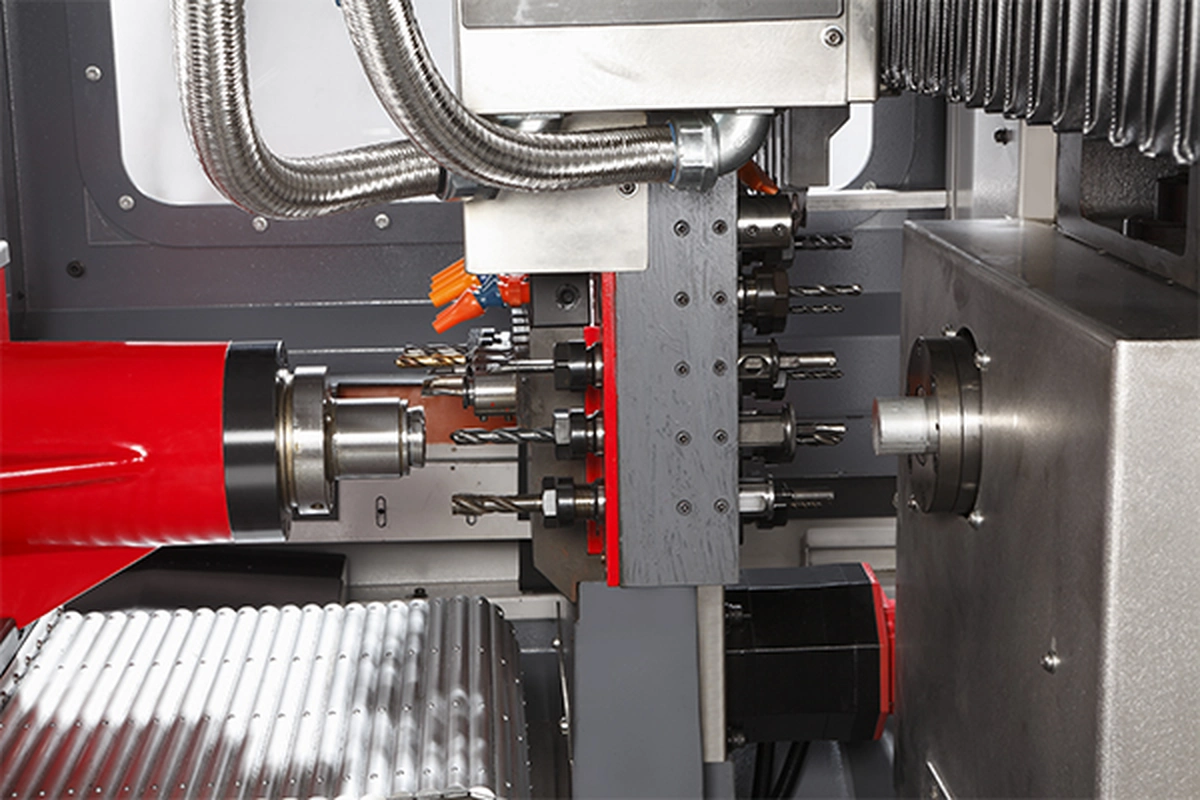

Spindle motors are primarily used in applications that require high-speed rotation and precision, such as in CNC (Computer Numerical Control) machining, milling, and grinding. These motors are designed to deliver constant speed and high torque, making them ideal for cutting, drilling, and shaping materials.

Servo Motors

Servo motors, on the other hand, are known for their precise control over position, speed, and torque. These motors are widely used in robotics, automation, and any application where accurate and responsive motion control is crucial. Servo motors are part of a closed-loop system, which allows for continuous feedback and adjustments to ensure the desired motion is achieved.

Technical Comparison

Design and Construction

Spindle Motors

- Spindle motors are typically AC motors designed to operate at very high speeds. They are built to handle the demands of continuous operation under high load conditions. The construction of spindle motors includes robust bearings and cooling mechanisms to manage the heat generated during high-speed operation.

- High-speed capabilities.

- Robust construction with heavy-duty bearings.

- Cooling systems to manage heat dissipation.

- Designed for continuous operation.

Servo Motors

- Servo motors can be either AC or DC motors and are part of a closed-loop control system. They are equipped with encoders or resolvers that provide feedback on the motor's position, speed, and torque. This feedback allows the servo drive to make real-time adjustments to maintain the desired motion.

- Precision control of position, speed, and torque.

- Equipped with encoders or resolvers for feedback.

- Part of a closed-loop control system.

- High responsiveness and accuracy.

Performance Characteristics

Speed and Torque

- Spindle Motors: Spindle motors are designed to operate at very high speeds, often reaching tens of thousands of RPM. They provide high torque at these speeds, which is essential for machining applications that require rapid material removal and precision.

- Servo Motors: While servo motors can also achieve high speeds, their primary strength lies in their ability to control speed and torque precisely. Servo motors excel in applications where varying speeds and torque are required, with rapid acceleration and deceleration.

Precision and Control

- Spindle Motors: Spindle motors offer excellent precision in maintaining constant speed and torque, which is crucial for consistent machining quality. However, they are not designed for applications that require frequent speed changes or complex motion profiles.

- Servo Motors: Servo motors are unparalleled in terms of precision and control. The feedback system allows for exact positioning and speed control, making servo motors ideal for tasks that require intricate motion control, such as in robotics and automation.

Applications

- Spindle Motors

- CNC Machining: High-speed cutting, drilling, and milling operations.

- Grinding Machines: Precision grinding of various materials.

- Engraving and Routing: High-speed engraving and routing of materials.

- Servo Motors

- Robotics: Precise motion control in robotic arms and automated systems.

- Conveyor Systems: Accurate control of speed and position in material handling.

- CNC Machining: When combined with spindle motors for complex motion control.

- Packaging and Labeling: High-speed, precise positioning in packaging lines.

Detailed Comparison

Cost and Complexity

- Spindle Motors: Generally, spindle motors are less complex and cheaper to implement than servo motors. However, the associated equipment, such as high-precision bearings and cooling systems, can add to the overall cost.

- Servo Motors: Servo systems are more complex due to the need for encoders, controllers, and feedback mechanisms. This complexity increases the initial cost and requires more sophisticated setup and maintenance.

Maintenance and Durability

- Spindle Motors: Designed for heavy-duty use, spindle motors require regular maintenance to ensure longevity, particularly concerning their bearings and cooling systems. They are built to withstand high operational demands.

- Servo Motors: Servo motors require maintenance of their feedback systems and controllers. While the motors themselves are robust, the complexity of the control systems can mean more frequent technical interventions to maintain peak performance.

Integration and Compatibility

- Spindle Motors: Spindle motors are relatively straightforward to integrate into machining centers and other high-speed applications. They are usually compatible with various CNC systems and can be adapted to different machining requirements.

- Servo Motors: Servo motors offer extensive flexibility and compatibility with a wide range of control systems. Their ability to provide precise motion control makes them suitable for integration into complex automated systems.

Conclusion

Choosing between spindle motors and servo motors depends on the specific requirements of the application. Spindle motors are ideal for high-speed, high-torque applications such as CNC machining and grinding, where constant speed and torque are paramount. On the other hand, servo motors excel in applications requiring precise control of position, speed, and torque, making them indispensable in robotics, automation, and complex motion control tasks. Although they are both motors, their specific application areas are different. Understanding the differences between these two types of motors can help you make more appropriate decisions based on the specific application.

Leave a Reply